Project Overview

During the AI4Industry Workshop, we developed an AI-powered system to detect and extract sample tubes in bulk within the pharmaceutical industry. The primary objective was to enhance the robustness of pick-and-place automation by integrating machine learning algorithms to detect and orient sample tubes accurately.

Data Preparation and Labeling

Dataset creation using Label Studio for manual annotation and bounding box generation.

Preprocessing techniques such as black-and-white conversion, contour detection, and pixel removal to enhance image quality.

Data was exported in YOLOv8 OBB format, ensuring compatibility with object detection models.

Model Training and Optimization

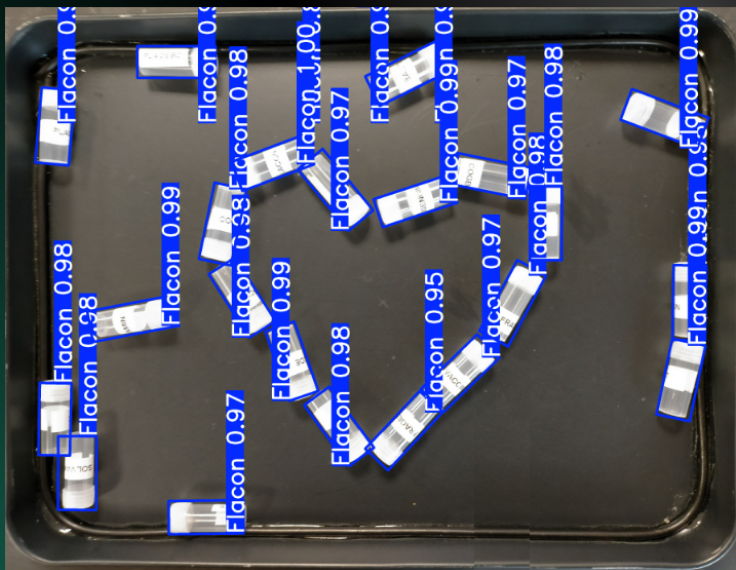

YOLOv8 OBB was chosen for its ability to detect and orient objects efficiently.

Fine-tuning was applied to optimize performance, ensuring high detection accuracy (70%-99%).

Performance evaluation included position deviation, orientation accuracy, and false positive reduction.

Results & Performance Evaluation

Detection accuracy:

Precision: 70%-99%, ensuring effective identification.

Future Enhancements

Increase dataset diversity with a broader range of images. Refine annotation strategies to improve object segmentation.